Don’t just think about 3D printers for plastic and metal. Think about 3D prototyping of absolutely everything.

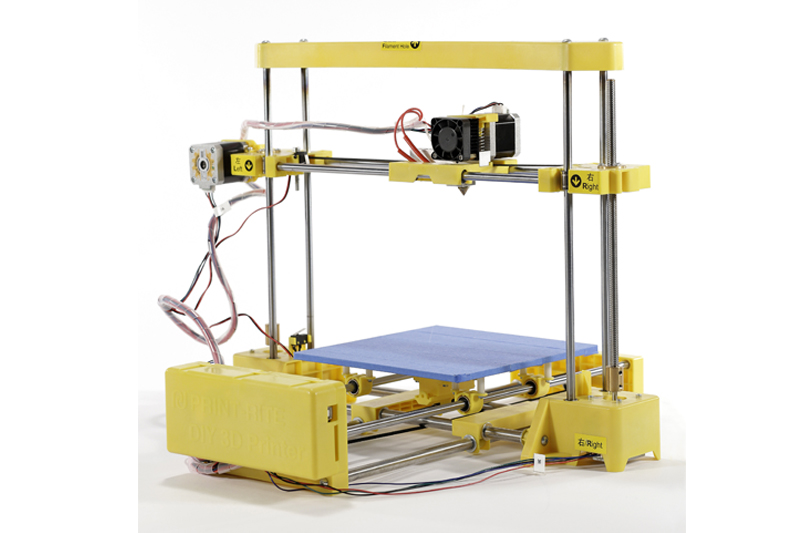

When I started my career, 3D printers were curiosities for engineers. We’d stare at the tiny printhead as it spat out layers of plastic to transform a digital file into a flimsy 3D object. In the 90’s we watched the cheapest 3D printers plummet from $18,000 to $300 in 10 years, even as they became 100 times faster. Staples began selling 3D printers a few years back and we knew the industry had changed:

You can even find a 3D printer on the International Space Station courtesy of Made in Space. That said, we’re still talking about a wonky line of business.

If you want to stay on top of the real action, look beyond 3D printers to quieter, but equally important, developments in rapid prototyping:

- Living tissue has been 3D printed at Scripps and a few other labs. Printed meat, anyone? Cartilage has already been printed successfully, and labs in China are working on ears…and livers!

- Last year, a San Francisco startup 3D printed an entire house (except the windows) for $10,000. When Eindhoven faced a shortages of bricklayers, they brought in a 3D house printer, essentially a huge robotic arm with a nozzle that squirts out a specially formulated cement, building the home layer-by-layer.

How do you think this will affect your business? Let me know. These changes will touch all of us.

Don’t think about 3D prototyping replacing high-volume manufacturing methods. Think about it completely reinventing your relationship with your customer.

Get used to it: The last word in new product introduction is no longer in the hands of manufacturers. Increasingly, the final say belongs to your customers.

We’re ten years into this trend in smartphones, which are really general-purpose computing platforms whose behavior can be completely customized with app downloads. My phone looks and behaves nothing like the phones of my millennial kids. In fact I should stop saying “phone” about a device that I almost never talk into anymore. It’s a piano metronome, a flashlight, and a home security display.

Even the Tesla is starting to feel less like a car and more like a general-purpose, customizable platform, with over-the-air downloads tweaking climate controls, enabling new dashcam functions, and eventually enabling a full self-driving system. (Let’s leave that one for a future newsletter.) Detroit carmakers love to make fun of Musk, but they’re flocking to Silicon Valley to research connected vehicles and over-the-air software downloads.

What about smaller consumer goods? Will clothing companies need to redefine their customer relationships? You bet. You can design your own trench coat with Burburry Bespoke and create your own shoes on Milk&Honey. Modular components let customers feel that they are designing their own products — and we’re headed beyond modules into a fully custom, printable future.

Belts, garments, shoes, food, toys…every industry will cede the final word on products to its customers. Get ready. I’d like to hear how you’re preparing for the next wave of additive and generative design.