When my son brought home some fraternity brothers to our place in Mountain View this summer, they got away from the Peninsula and spent their time just where you’d expect: San Francisco, Oakland, and Santa Cruz. However I got some mileage by recommending the Tesla Factory Tour in Fremont.

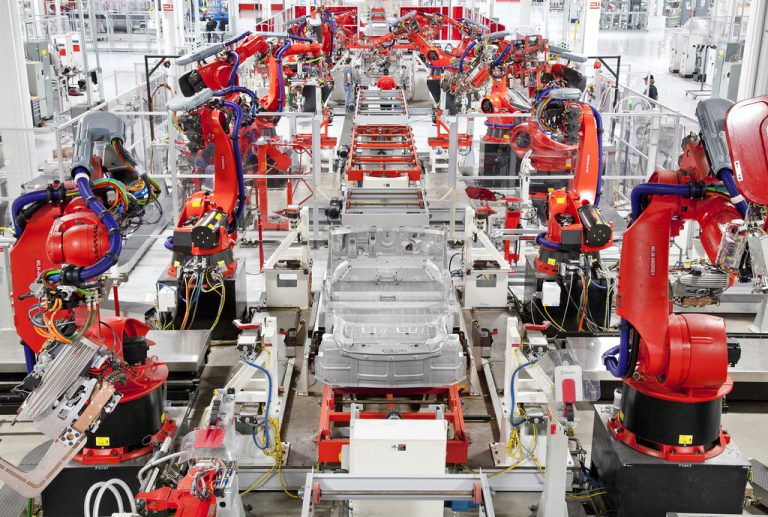

One quick observation to share with you, after taking a tram through the second largest building in the world, 5.5 million square feet of frenetic robots working on a hellacious number of vehicles.

Tesla is incredibly proud of its heritage…

Tesla takes great pride in building on a legacy of older automotive infrastructure. The building was purchased from NUMMI, a joint venture between Toyota and General Motors, and they’re proud to upgrade it and keep it in operation. Our adorable tour guide swelled with pride as she told us how a massive stamping press was purchased from a truck manufacturer.

…but Tesla takes no pride in partnering.

We learned on the tour that Tesla builds damn near all the ingredients that go into their vehicles. Our guide talked about fabricating everything from seat fabrics to electrical connectors. Telsa’s approach is completely distinct from the car manufacturers I work with, who focus on drivetrain and assembly process.

On the tour, they made it clear that they had to integrate vertically because of their “first principles” approach: No one else had the required parts, systems, and services Tesla needed. Going the supplier route made no sense. Well, maybe. I think we’re seeing an uncompromising culture that prefers to build rather than buy.

We’ll see how Tesla manages its scale over the next few years. They’re done a remarkable job designing the “machine that creates the machine”, and the factory itself is a remarkable product. If Tesla can integrate value as competently as it integrates manufacturing, there will be no stopping them.

Have you taken the tour? I’d love to hear your observations.